We provide new product

development services

- —Product / industrial design

- —UX & UI design

- —Project management

- —Innovation consultancy

- —Compliance

- —ISO 13485 certified

- —Medical design

- —Design for industry

- —Connectivity & smart

- —Robotics & mechatronics

- —Supplier network

- —Cross industry perspective

- —30+ years experience

- —Brand driven innovation

- —Brand identity design

- —Competitor research

- —Creative facilitation

- —Customer / patient journey mapping

- —User research and testing

- —Design guidelines

- —Design research

- —Design thinking facilitation

- —Development roadmapping

- —Development strategy

- —Future vision creation

- —Intellectual property strategy

- —Low fidelity prototyping

- —Moodboard creation

- —Regulatory/ legal framework

- —Service design

- —Sustainability with LCA approach

- —Technological research

- —Technology development

- —Trend research

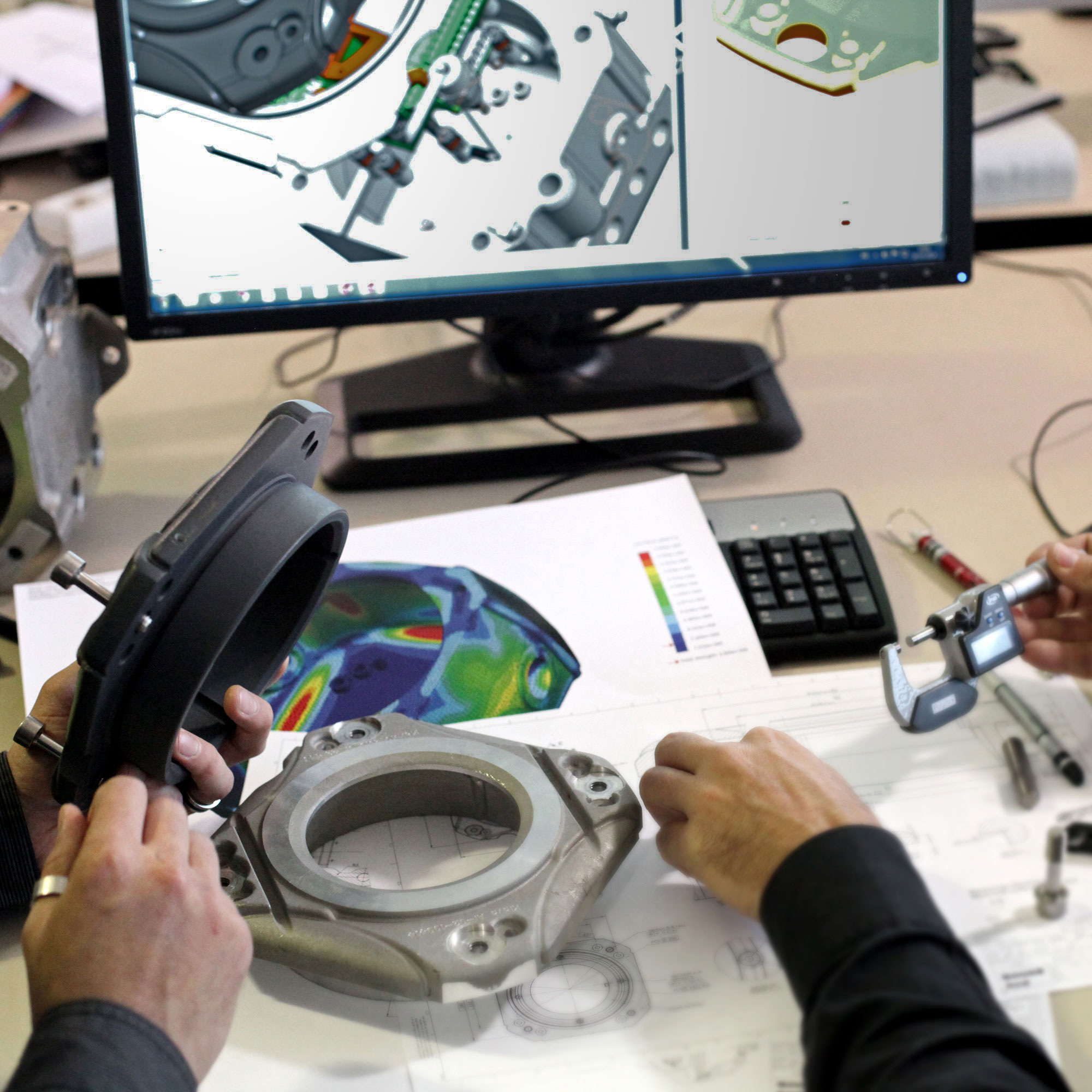

- —3D Cad modeling

- —3D printing

- —Aesthetic design

- —Color study & advice

- —Concept development

- —VR simulations

- —Connected product design

- —Design for cost reduction

- —Electronics prototyping

- —Explosion safety (ATEX)

- —Fabrics & softgoods

- —Idea generation

- —Low-power devices

- —Mock-ups & prototypes

- —Photo realistic concept visualisation

- —Product achitecture

- —Proof of principle

- —System architecture design

- —Technical working principles

- —User experience design

- —User Interface design

- —Bluetooth Low Energy

- —Cable management

- —Climate conditioned testing

- —Colour, Material and Finish

- —Compliant reporting

- —Tolerance analysis

- —Design specifications

- —Detail aesthetic design

- —Detail integrated design

- —Detailed CAD design

- —EMC/ESD precompliance testing

- —FEM

- —Functional design testing

- —IoT hardware design

- —IPXX testing

- —Mechatronics

- —Near Field Communication

- —PCB design

- —Power management

- —Structural calculations and FEM

- —Test plan & verification testing

- —Assembly manual

- —Bill of Materials (BOM)

- —Breadboarding

- —Certification proces support

- —Component sourcing

- —Cost price by quotation

- —Design for aluminium injection moulding

- —Design for manufacturing

- —Design for plastic injection moulding

- —Drawings for production

- —Manufacturing network

- —Sheet metal engineering

- —Sourcing

- —Spec-sheets

- —Supplier management

- —Technical File / TPD preparation

- —Validation testing

- —Manufacturer specifications

- —Packaging design

- —Product documentation

- —Production preparation

- —Production sample evaluation (FOT, SOT)

- —Supplier management

- —Supplier network (Netherlands, europe, the world)

Integrated approach

Talent, experience & open cooperation

Our process